Wheatland Tube Introduces Free App That Calculates Savings from 20′ EMT

With our recent announcement of a free mobile and tablet application that enables electrical contractors to calculate the monetary difference when using 20′ rather than 10′ EMT, I wanted to provide you a little background on steel rigid conduit and why a few extra feet can save you and our

customer money.

A Brief History

Steel Rigid and EMT has been a “mature product” for as long as anyone can remember. The first rigid conduit system was probably the system installed by Greenfield in 1888; zinc tubes with copper elbows were used. Once people recognized the merits of electrical raceway systems, conduits were offered and installed made of insulating paper tubes, woven fabrics, fiber and even “flexible glass” as the insulating and sheathing material. Eventually paper tubes encased in steel armor or thin sheet brass were offered to provide greater physical protection.

By 1890, wires were being installed in plain unlined gas pipe as the simplicity and low cost combined with the added strength made this a preferred wiring method. The next twenty five years saw further developments in steel rigid conduit with hot-dipped galvanized rigid product finally being available around 1912.

As early as December of 1928, “Electrical World” mentioned a reduced wall raceway, “Electrical Metallic Tubing”, which was approved by the National Electric Code in limited applications.

It appears that during this period of product development, rigid and EMT was always sold with a maximum length of ten feet.

With the harmonization of the North American codes and standards, the restrictive language limiting the conduit length to 10 feet was removed. This opened up the possibilities for the conduit producers to offer longer lengths. Now, 20 Foot EMT is available in all Trade Sizes (1/2 – 4) and 20 Foot Hot Dipped Rigid Steel Conduit is available in Trade Sizes 2-6.

Simple Math

Simple Math

Twenty Foot EMT and Rigid Steel Conduit offers immediate and obvious labor savings for the electrical contractor without requiring an investment in equipment, training or time. Every electrical installation offers different challenges. While not suitable for every job (Manhattan jobsites come

to mind, for example), 20 Foot EMT and Rigid may be a simple way to reduce the installed costs of steel EMT or Rigid.

One of the first jobs that used 20 Foot Rigid was a prison in Upstate New York, where 20 foot lengths of 4 inch Steel Rigid, direct buried on a gravel bed, were used to connect all the manhole access points. The DFW Airport People- Mover has 6 inch Rigid installed as high as 30 feet off the

ground. Both jobs were perfect installations for 20 Foot Rigid. Some recent 20 Foot EMT jobs have included off-site Data Centers, Distribution Centers, Hospitals, and Shopping Centers. Some contractors that pre-fabricate stub-ups etc. have standardized on 20 Foot EMT to reduce waste.

Less Handling, Less Labor and Fewer Couplings

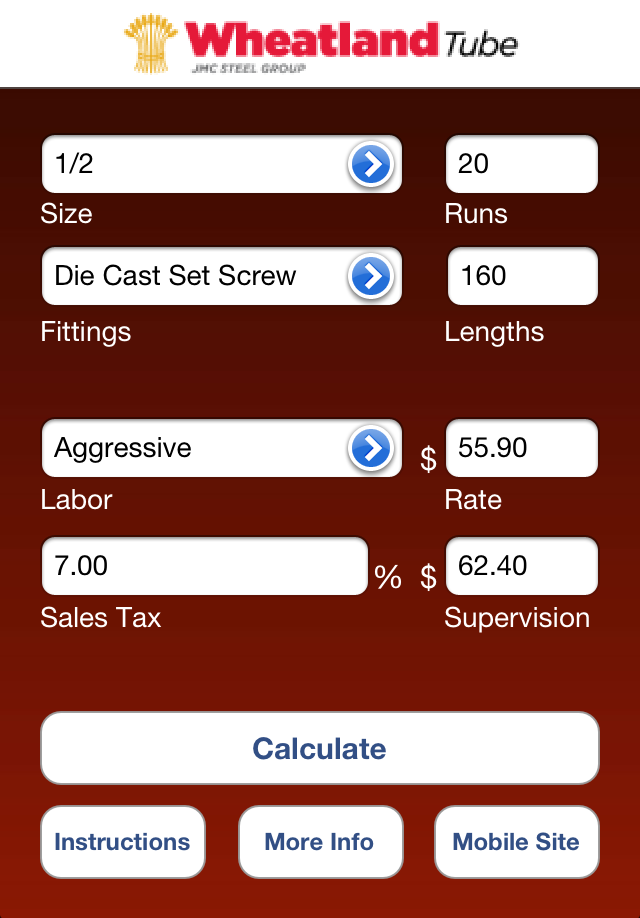

This free calculator app — Wheatland Tube’s first — is easy to download and use. It is available at wheatland.com/worksmarter, as well as the App Store and Google Play as “EMT Calc.”