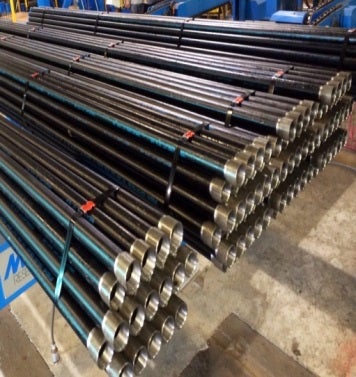

Wheatland Tube’s Plant Revitalization Continues

Back in July, we announced the revitalization program that our Council Avenue plant is undergoing and how it will benefit our customers. Since our last post, we’ve made great progress with the upgrades, and we continue to work diligently to complete this project so our customers receive an even better product from Wheatland Tube.

Well into phase five of six total phases, here are some highlights of the project:

• We have installed and commissioned an 8-head high speeds hydro and flush system. The high speed hydro tester will help eliminate operational bottle necks, enhancing our product throughput, and improving cycle times and customer service. The flush system will improve the ID (inside diameter) of our product, and both systems will add MIC shield to our product.

• We have installed and commissioned a new 4 head PMC threader. This new threader is an upgrade from our current threading machine. It will produce a world-class thread, while the unit automatically installs thread protectors. The new threader will install thread protectors (TPs) on one end of the pipe, while a coupling is applied to the other end. The pipe is then put into a hex-bundle which helps in stacking/storing the material.

• Improved painting, stenciling and packing expertise, resulting in an overall higher quality product.

• Increased efficiencies. With MAIR conveyance we have tied the mill in with our plain ending, NDT (eddy current testing), hydro, paint and thread lines processes for a one-piece (of pipe) flow through the entire operation. The conveyors will transfer the material through each operational step at a constant (no bottlenecks) pace.

• Enhanced product (cleaner) ID because of the improved and additional air and wash out systems installed.

As we are currently installing a new plain ender, we plan to have it operational in a couple weeks. The final phase of our plant revitalization is to install an additional plain ender. There are plans to have this go in at end of December, thus completing phase five of the project just in time for 2016!

Tags: Manufacturing, Plant Upgrade, Standard Pipe